Occupational Safety and Health

Occupational Health and Safety

TTY Biopharm provides Labor Insurance and National Health Insurance; besides, group insurance, accident insurance, occupational hazard insurance, cancer insurance, and business travel insurance also covers for all employees. In addition, employee health examinations are organized on yearly basis to monitor employees' healthy condition.

The company has purchased public liability insurance for all work stations of the company and its factories. Inspections of public safety equipment (including firefighting equipment) in buildings are reported to the competent authority on a regular basis pursuant to relevant laws and regulations. TTY has acquired licenses for its firefighting management personnel, formulates fire safety plans for all work stations, and maintains the safety of workplace firefighting equipment.

We have assembled a Safety and Health Committee in accordance with Article 11 of the "Occupational Safety and Health Act" to review occupational safety issues. PDC Neihu is excluded from the regulatory standards but formed a Safety and Health Management Promotion Team to take charge of relevant affairs. Members call regular meetings and review occupational safety issues, ensuring occupational health and safety supervision, as well as planning suggestions accordingly. At least a third of the members are accounted for by labor representatives.

For the prevention of occupational hazard and protection of employees' health and safety, the company has followed Occupational Safety and Health Act and related regulations by establishing the "Occupational Safety and Health Code of Conduct" and "Occupational Safety and Health Management Program," and deploying occupational safety and health units, officers and first aid personnel at factory sites. Furthermore, safety and health training is conducted on yearly basis.

TTY Biopharm recognizes the importance of protection measures within the work environment and for human safety, which is why we organize an orientation program called "Occupational Safety and Health Series" for new recruits at factory sites. This program covers several topics including general safety and health training, safety awareness, health promotion at work, and the correct way to use face masks. Learning assessments are also introduced as part of the training process to ensure that employees are learning towards the right direction and developing the proper awareness towards safety protection measures available in the workplace.

TTY also set up a temporary occupational nursing and physician service in accordance with the regulations, so colleagues can easily obtain professional medical assistance. In 2023, TTY promoted 6 health topics through email, including "Nine Symptoms to See If You Have a Damp Constitution", "Bridge Exercise Rescue the Corpulent Waist",

"Fast Steaming for 5 Minutes to Retain the Most Nutrients", "Four Steps for A Full Relaxation of the Whole Body's Muscle and Vessel", "Shrinking the Abdomen to Stimulate the Spinal Bones", and "Three Cups of Tea with These Three Ingredients to Easily Cultivate Anti-inflammatory Constitution", to maintain the physical and mental health of our colleagues.

TTY Biopharm provides Labor Insurance and National Health Insurance; besides, group insurance, accident insurance, occupational hazard insurance, cancer insurance, and business travel insurance also covers for all employees. In addition, employee health examinations are organized on yearly basis to monitor employees' healthy condition.

The company has purchased public liability insurance for all work stations of the company and its factories. Inspections of public safety equipment (including firefighting equipment) in buildings are reported to the competent authority on a regular basis pursuant to relevant laws and regulations. TTY has acquired licenses for its firefighting management personnel, formulates fire safety plans for all work stations, and maintains the safety of workplace firefighting equipment.

We have assembled a Safety and Health Committee in accordance with Article 11 of the "Occupational Safety and Health Act" to review occupational safety issues. PDC Neihu is excluded from the regulatory standards but formed a Safety and Health Management Promotion Team to take charge of relevant affairs. Members call regular meetings and review occupational safety issues, ensuring occupational health and safety supervision, as well as planning suggestions accordingly. At least a third of the members are accounted for by labor representatives.

For the prevention of occupational hazard and protection of employees' health and safety, the company has followed Occupational Safety and Health Act and related regulations by establishing the "Occupational Safety and Health Code of Conduct" and "Occupational Safety and Health Management Program," and deploying occupational safety and health units, officers and first aid personnel at factory sites. Furthermore, safety and health training is conducted on yearly basis.

TTY Biopharm recognizes the importance of protection measures within the work environment and for human safety, which is why we organize an orientation program called "Occupational Safety and Health Series" for new recruits at factory sites. This program covers several topics including general safety and health training, safety awareness, health promotion at work, and the correct way to use face masks. Learning assessments are also introduced as part of the training process to ensure that employees are learning towards the right direction and developing the proper awareness towards safety protection measures available in the workplace.

TTY also set up a temporary occupational nursing and physician service in accordance with the regulations, so colleagues can easily obtain professional medical assistance. In 2023, TTY promoted 6 health topics through email, including "Nine Symptoms to See If You Have a Damp Constitution", "Bridge Exercise Rescue the Corpulent Waist",

"Fast Steaming for 5 Minutes to Retain the Most Nutrients", "Four Steps for A Full Relaxation of the Whole Body's Muscle and Vessel", "Shrinking the Abdomen to Stimulate the Spinal Bones", and "Three Cups of Tea with These Three Ingredients to Easily Cultivate Anti-inflammatory Constitution", to maintain the physical and mental health of our colleagues.

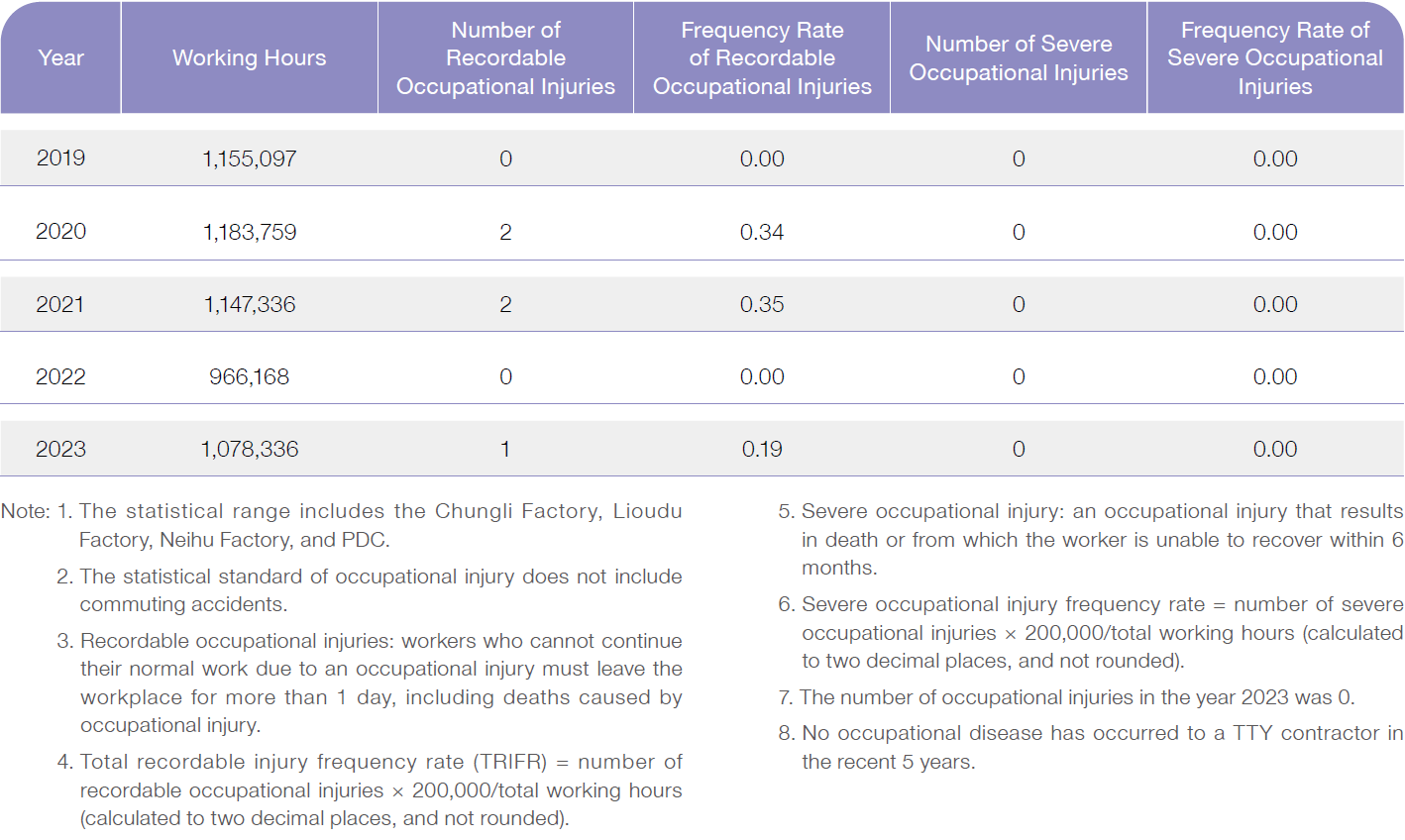

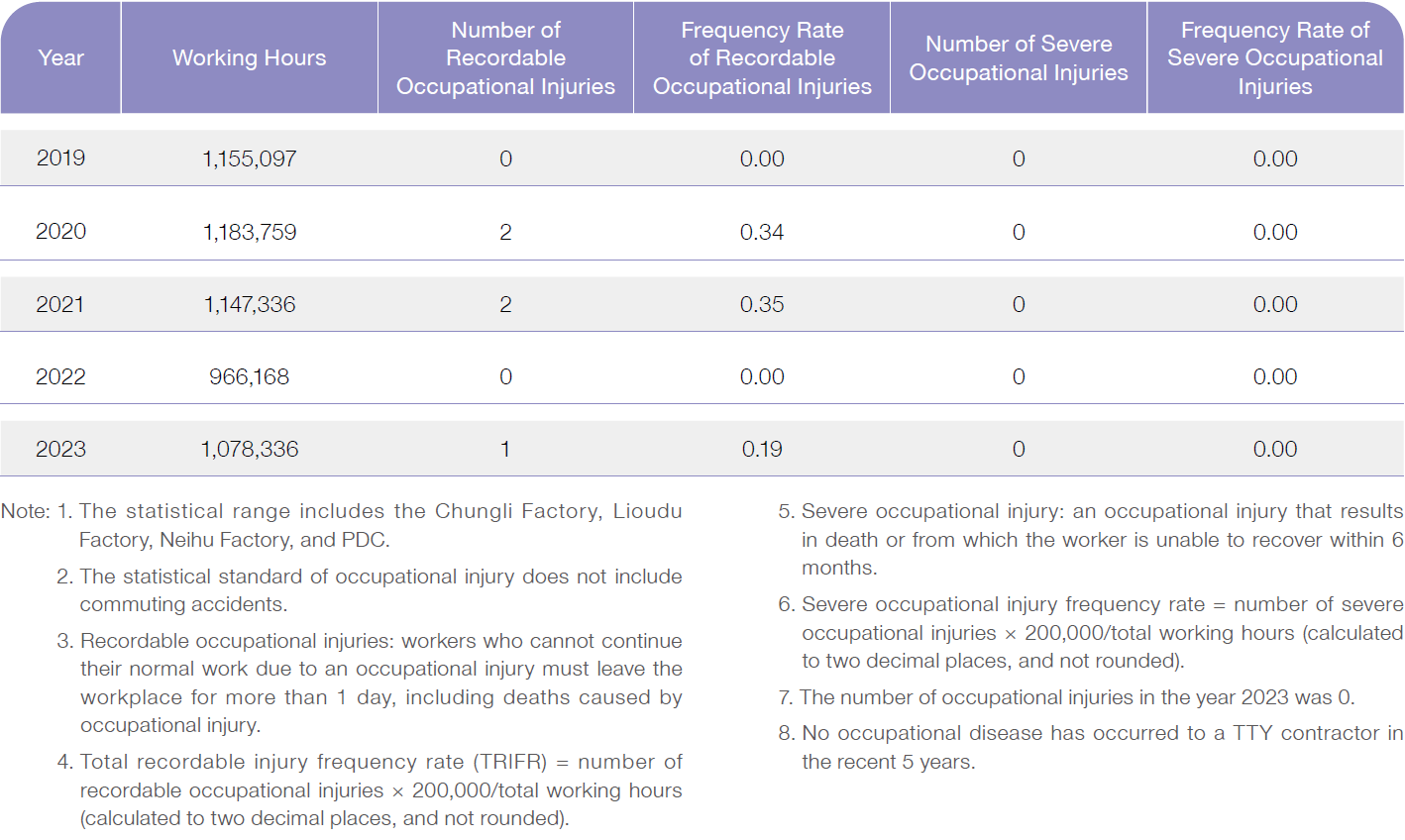

Statistics on Occupational Hazard

TTY has adopted preventive measures to address certain dangers in the work environment, including noise, heat, dust, specialized operations and organic solvents.

For employees who are exposed to special hazards such as organic solvents, specialized operations or noise, we provides them with protective gears (including face masks, gloves, goggles and lab suits) and strictly asks them to wear complete gears before commencing work activities. Furthermore, employees are instructed to handle organic solvents and hazardous chemicals only under the fume hood. To prevent noise hazard, ear plugs and ear muffs are provided to employees working in noisy environment, whereas specialized noise health checkups are arranged on a yearly basis. At factory sites, walk-around inspections and contractor safety management are conducted regularly to ensure that all personnel are able to complete their job duties with the utmost safety.

For employees who are exposed to special hazards such as organic solvents, specialized operations or noise, we provides them with protective gears (including face masks, gloves, goggles and lab suits) and strictly asks them to wear complete gears before commencing work activities. Furthermore, employees are instructed to handle organic solvents and hazardous chemicals only under the fume hood. To prevent noise hazard, ear plugs and ear muffs are provided to employees working in noisy environment, whereas specialized noise health checkups are arranged on a yearly basis. At factory sites, walk-around inspections and contractor safety management are conducted regularly to ensure that all personnel are able to complete their job duties with the utmost safety.

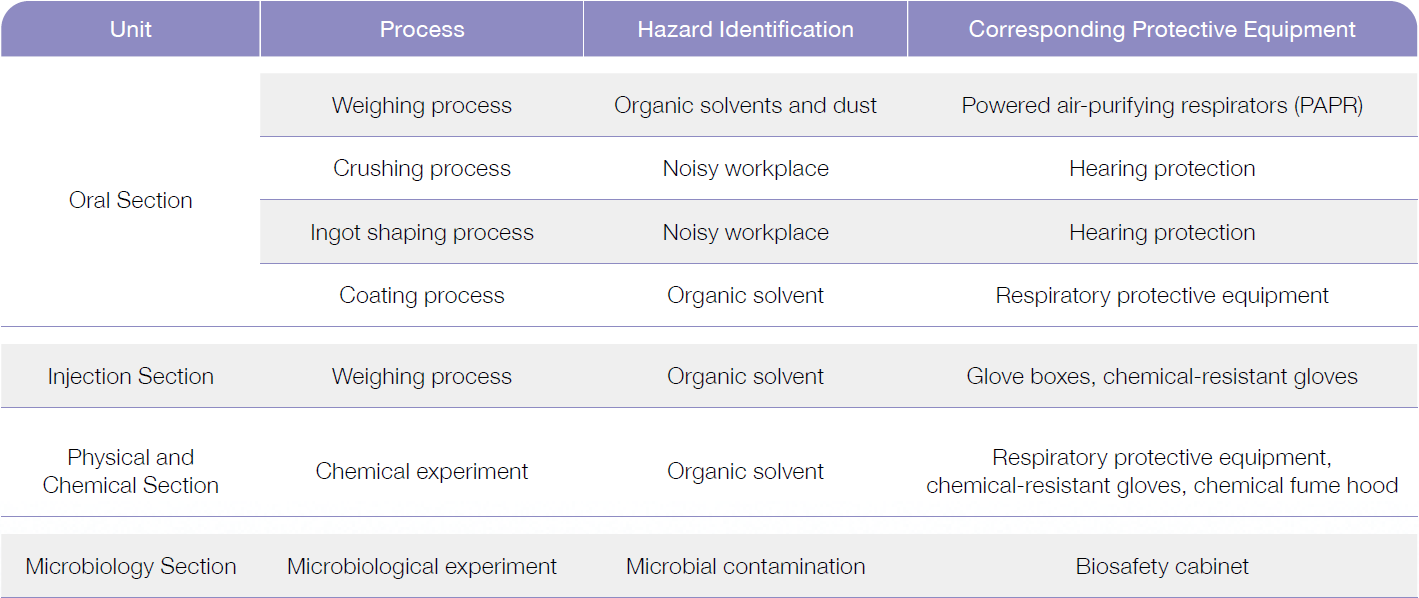

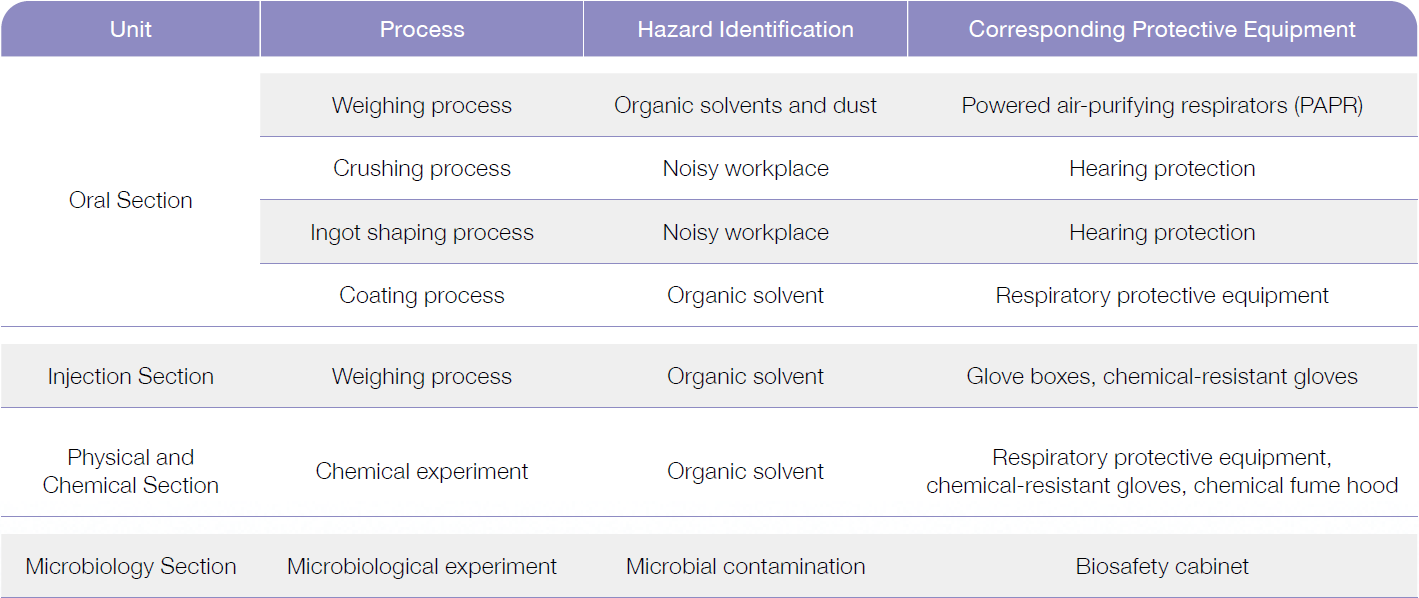

Protective Equipment

We value and protect the safety of each product we make. In the area of personnel safety, PPE (personal protective equipment) is used to keep our operators from certain occupational hazards. In accordance with relevant occupational safety and health laws and regulations, TTY carries out environmental harmful component inspections for different processes/production lines to assess the necessity and effectiveness of protective equipment and determine the working environment.

For example, glove boxes effectively allows factory workers to avoid contact with chemicals, and spill kits are provided for an immediate response to chemical spillages or leakages. This ensures that injuries can be contained and the disaster rate moderated. In addition, PPE is updated depending on the process requirements and use conditions so that production line employees receive maximum protection. For example, masks and protective clothing are all disposable and respiratory protective equipment is replaced according to the degree of dust adsorption.

Emergency Responses

TTY Biopharm uses a wide variety of chemicals. Relevant departments have formulated emergency response procedures to prevent dangers such as chemical leakages causing pollution of the environment, fires, and explosions. Chemical leakage handling, protective clothing practice, firefighting, evacuation, and emergency relief drills are conducted in cooperation with on-site departments on an annual basis to reinforce emergency response concepts and skills.

A chemical leakage treatment vehicle is dispatched to the factory, allowing employees to respond urgently and minimize the incident.

TTY Biopharm uses a wide variety of chemicals. Relevant departments have formulated emergency response procedures to prevent dangers such as chemical leakages causing pollution of the environment, fires, and explosions. Chemical leakage handling, protective clothing practice, firefighting, evacuation, and emergency relief drills are conducted in cooperation with on-site departments on an annual basis to reinforce emergency response concepts and skills.

A chemical leakage treatment vehicle is dispatched to the factory, allowing employees to respond urgently and minimize the incident.

Employee Physical and Health Management

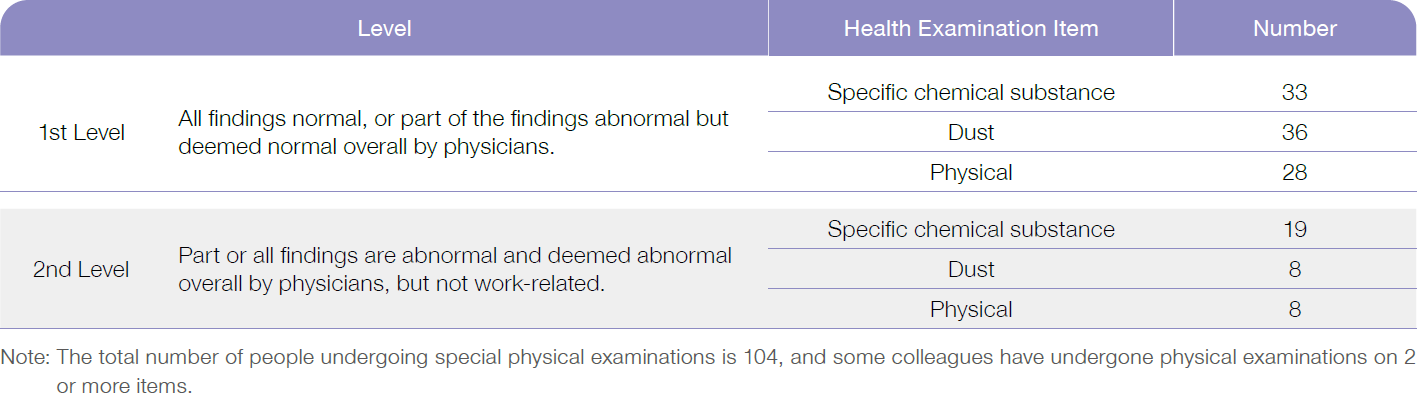

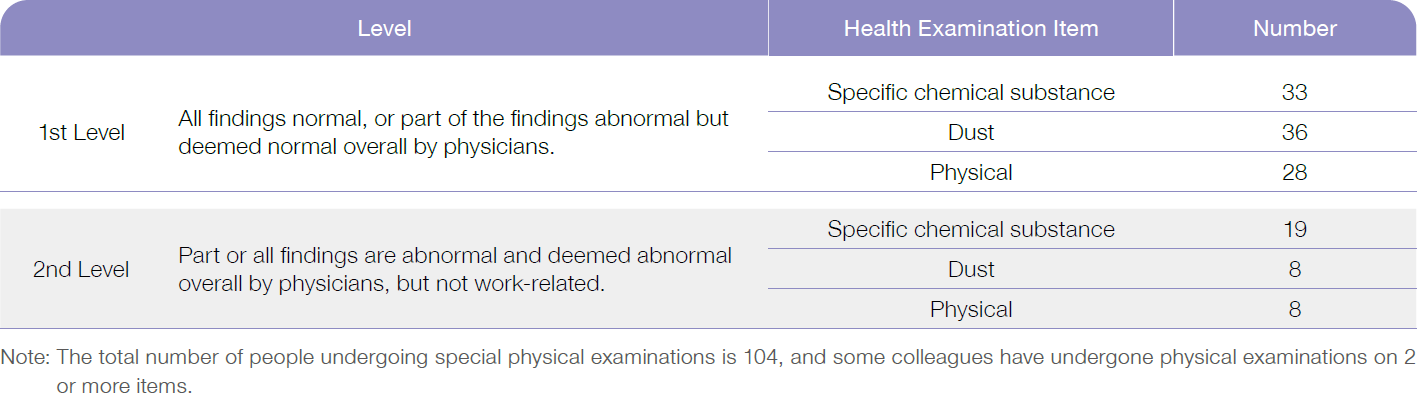

| Health Management Degree | 1st Level | 2nd Level | 3rd Level | 4th Level |

|---|---|---|---|---|

| Special Health Examination | All findings normal, or part of the findings abnormal but overall deemed as normal by physicians. | Part or all of the findings abnormal and overall deemed abnormal by physicians, but not work-related. | Part or all of the findings abnormal and overall deemed abnormal by physicians but failed to establish the correlation between the results and the work. Further assessment by occupational physicians is required. | Part or all of the findings abnormal and overall deemed abnormal by physicians, and are work-related. |

Pursuant to the regulations set forth in Article 6, Article 20, Article 21, and Article 22 of the Occupational Safety and Health Act, employers are required to conduct medical examinations and health checks. TTY Biopharm conducts health exams for employees of all factories. These exams include general and special health check items. The company offers regular and special exams for all employees on an annual basis.

In the year 2023, a total of 104 employees underwent special physical examinations, and their health management classification was implemented according to the regulations. If the health examination results are about personnel above level 2 management, nurses and professional medical specialists will perform health education and health follow-up examinations, and, if necessary, on-site assessments of suspected work-related injuries may be conducted. No personnel above level 3 management and no abnormalities in physical examinations caused by special operations were detected this year.

In the year 2023, a total of 104 employees underwent special physical examinations, and their health management classification was implemented according to the regulations. If the health examination results are about personnel above level 2 management, nurses and professional medical specialists will perform health education and health follow-up examinations, and, if necessary, on-site assessments of suspected work-related injuries may be conducted. No personnel above level 3 management and no abnormalities in physical examinations caused by special operations were detected this year.

Safety and Health Workshops

After newly inducted employees report for duty, they have to participate in Work Safety and Health Workshops. This training makes employees familiar with them with the characteristics and dangers of various chemical substances (dangerous and hazardous objects) present in work environments or during operations inside factories as well as prescribed methods and operations.

When newly inducted employees report for duty in production areas, they are educated on the steps and procedures and important precautions pertaining to production process area operations by certified instructors before they are given access to production lines. Production unit executives constantly monitor compliance with operating standards and procedures by newly inducted employees. Non-complying employees receive guidance to ensure compliance.

Safety and health workshops (in accordance with production conditions) are organized on a non-scheduled basis to meet the needs of active duty staff. These courses are planned by labor safety and health administrators, while factory, production unit, and QC unit executives or other qualified personnel serve as instructors.

When newly inducted employees report for duty in production areas, they are educated on the steps and procedures and important precautions pertaining to production process area operations by certified instructors before they are given access to production lines. Production unit executives constantly monitor compliance with operating standards and procedures by newly inducted employees. Non-complying employees receive guidance to ensure compliance.

Safety and health workshops (in accordance with production conditions) are organized on a non-scheduled basis to meet the needs of active duty staff. These courses are planned by labor safety and health administrators, while factory, production unit, and QC unit executives or other qualified personnel serve as instructors.

Personnel and Environment Inspections

During production processes, raw materials, personnel, and environments are key and indispensable components of product safety. All TTY factories therefore strictly abide by norms governing personnel and workplaces. Personal hygiene habits, hand hygiene, wearing and cleanliness of work clothes are required daily inspection items prior to initiation of production operations. Production environment inspections include machinery, equipment, packing materials, airborne microbes, and the quality of the water used for production processes in the factories to ensure implementation of various controls. These inspections guarantee that consumers are provided with safe, healthy, and worry-free products.