TTY strived every effort to reduce air pollution. The two main manufacturing sites adopted source classification to minimize air pollutants during manufacturing processes. Treatment technology at multiple sections has helped elevate the processing performance of the terminal preventive facility. Annual air pollutant discharge inspections and implementation have resulted in maintenance and training put in place to ensure that pollutants fall within or are superior to the criteria of the Stationary Pollution Source Air Pollutant Emissions Standards. In 2024, the 2 manufacturing sites of Lioudu and Chungli factories discharged particle pollutants of PM 258.205 kg, SO2 12.649 kg, and NOX 440.28 kg in total.

2023~2024 TTY’s Material Gas Emission

| Year | Site | PM | SO2 | NOX |

| 2023 | Lioudu Factory(unit:kg) | 3.520 | 6.09 | 250.08 |

| Chungli Factory (unit:kg) | 2.222 | 4.15 | 60.00 | |

| Total | 5.742 | 10.24 | 310.08 | |

| 2024 | Lioudu Factory(unit:kg) | 91.905 | 7.969 | 350.28 |

| Chungli Factory(unit:kg) | 166.30 | 4.68 | 90.00 | |

| Total | 258.205 | 12.649 | 440.28 |

Note: The data from the verification report designated by the factories is utilized to calculate emissions (emissions per hour x operation hours of boilers per day x working days per year).

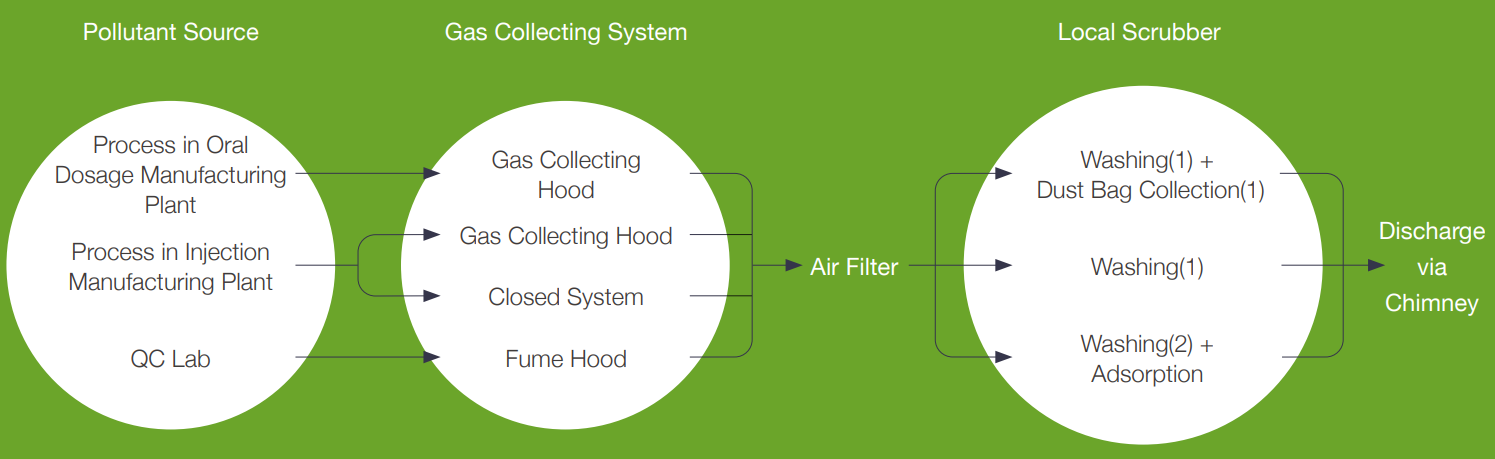

Air Pollutant Control Process

Taking control from the beginning is the most effective way to minimize pollutants. In TTY, the "effective minimization on emission sources and enhanced treatment at the terminal preventive facility" is our current practice. Starting at the source in phase I, pollutants are classified based on their nature, such as dust, organic, solvents, and odors. The local scrubber is then treated through washing, following which activated carbon absorbers or bag-type dust collectors process the remaining emissions before they are released into the air. The pollutant concentration now complies with the relevant regulations. The sectional treatment is a perfect, all-direction solution to making air emission treatment more effective.

Stationary Pollution Source Measurements

| Chungli Factory | PM(mg/Nm3) | SO2(ppm) | NOx(ppm) |

|---|---|---|---|

| Stationary Pollution Source Air Pollutant Emissions Standards | 30 | 50 | 100 |

| Gas Boiler (P001) | 1 | 1 | 17 |

| Gas Boiler (P002) | 1 | 1 | 34 |

| Lioudu Factory | PM(mg/Nm3) | SO2(ppm) | NOx(ppm) |

|---|---|---|---|

| Stationary Pollution Source Air Pollutant Emissions Standards | 30 | 50 | 100 |

| Gas boiler (P001) | 1 | 1 | 60 |

| Gas Boiler (P002) | (ND) | 1 | 63 |

| Gas Boiler (P003) | 1 | 1 | 65 |

Note:1. No Persistent Organic Pollutant (POP), Volatile Organic Pollutant (VOP) and Hazardous Air Pollutant (HAP) is discharged from Lioudu or Chungli factories.