TTY formulates water conservation policies and plans in accordance with local government regulations and inspection standards in various countries, and continues the monitor of water consumption in critical manufacture sites and has accumulated usage data over the years. In the future, the overall water saving policy will be further expanded to systematic water management, systematic measures related to water resource management are as follow:

• Inclusive of the circulation system, recycle and reuse of chilling tower water

• Chilling procedure upgrades, better heat recovery rate, and lower water demand

• Disseminated across all employee levels up to managerial for fundamental actions

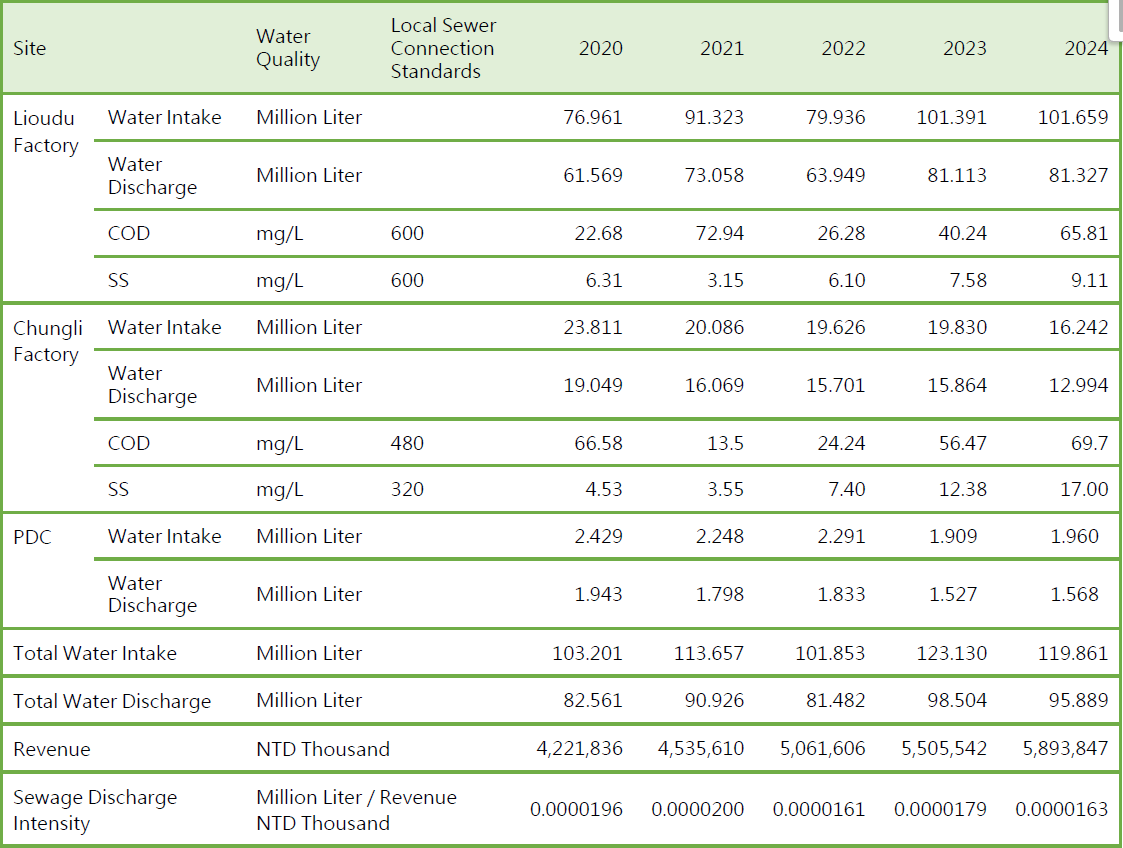

TTY Water Discharge and Water Quality Monitoring Results (Unit: Million liter/Revenue Thousand NTD)

The water for Lioudu, Chungli, and Neihu (Neihu factory + Pharmaceutical Development Center) comes 100% from Water Plants. As indicated in the WRI (World Resources Institute)'s Aqueduct Water Risk Atlas, Taiwan is categorized as a low-medium (1-2) area in the Baseline Water Stress Map. There is no underground water usage to cause an impact on its source. TTY Biopharm does not discharge water containing a high concentration of chemical substances. Low-concentration wastewater first goes through primary treatment in the factory before being channeled to the sewage treatment plant in the industrial park for final treatment. Within national effluent standards, the treated wastewater is discharged into receiving waters, thereby reducing environmental degradation.

In 2024, the water intake of TTY's Lioudu and Chungli factories and the Neihu Pharmaceutical Development Center was approximately 119.861 million liters and sewage discharge was about 95.889 million liters; sewage discharge slightly decreased by about 2.615 million liters compared to the previous year. No sewage was discharged by TTY as a result of an unscheduled leakage or overflow. Furthermore, all sewage discharged complies with the Water Pollution Prevention Act, local governance laws, and sewage treatment plant’s Incoming Water Quality Standards in the industrial zone. The COD and SS in sewage discharged by the Lioudu and Chungli factories are far lower than local sewer connection standards without impacting nature and biological diversity.

TTY wishes to mitigate the environmental impact caused by production and has partnered with NCU to develop a process to recycle As ions, ensuring As concentration in wastewater falls within the discharge limit. It is expected to improve the manufacturing process and sewage treatment efficacy. The technology applies practical needs and takes care of both high and low As concentration recycling, a great example of a business concept that follows recycling, purification, and sustainable circulation.

With the terrific achievement of As ion recycling, TTY was invited by ITRI to share at the “TASS2020 Asia’s Sustainable Supply & Circular Economy Conference and Exhibition” based on their most recent study results. In the future, TTY will ensure relevant regulation compliance on local and international levels and contribute to the sustainability of our environment.