Supplier Management

As a Sustainable Enterprise, not only to invest and support the CSR issues, we also encourages all suppliers of pharmaceutical industry to protect and respect our environment. We will speak for CSR and awaken the public to pay attention to our environment.

Policy

- Quality Assurance:

Assess and onsite due diligence to ensure quality system and quality supply.

- Stable Quantity:

Multiple suppliers to keep flexible and stabilized supply source and quantity.

- Deliver Time Reduction:

Credible suppliers with qualified delivery capability to keep cycle time reduction effective.

- Sustainability:

Long-term partnership to build stable development and sustainable supply chain. TTY demands suppliers to observe eco-friendly actions, constant safety and security, human rights, and CSR, as well a risk management and sustainable operation plan.

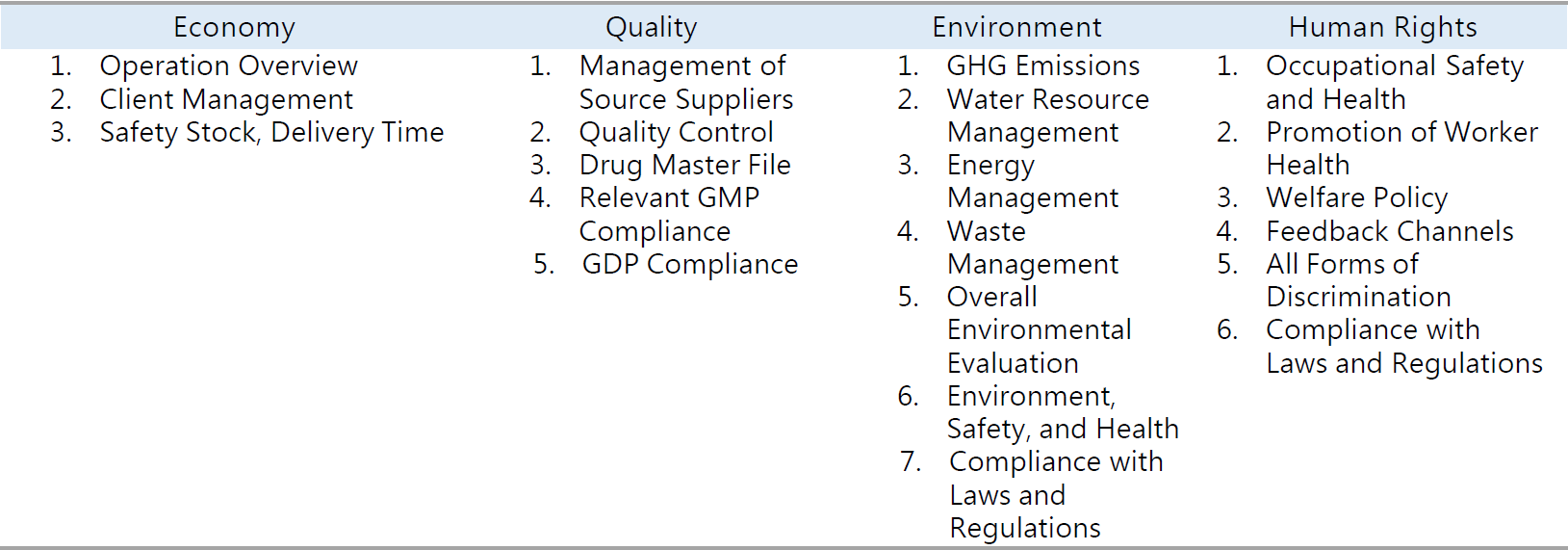

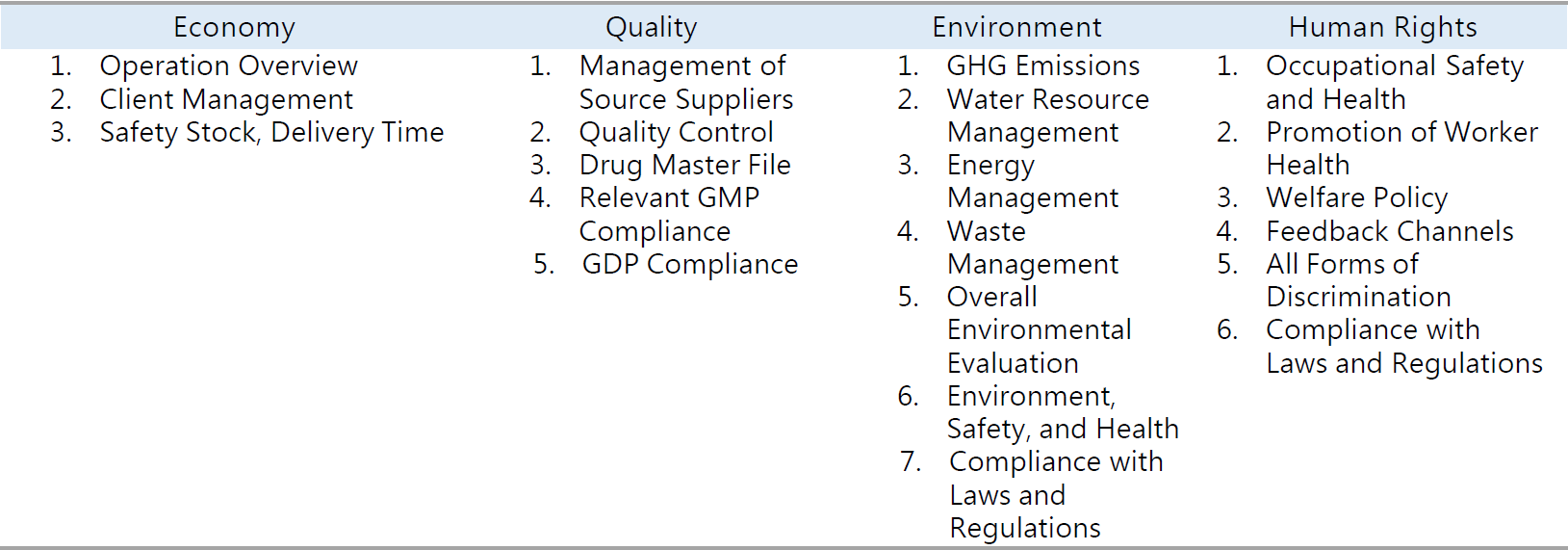

Supplier Sustainability Management Assessment

the “Supplier Sustainability Management Assessment” serves as a standard to select and assess new suppliers, and manage the documentations of the qualified suppliers.

the “Supplier Sustainability Management Assessment” serves as a standard to select and assess new suppliers, and manage the documentations of the qualified suppliers.

Choose New Suppliers

- Financial Status

- Control and Management over Quality System

- Organization and Management

- Capability to Execute Orders

- CSR Implementation Capability

The Eligibility of New Suppliers

The completion and stability of quality system and GMP compliance, and knowing the condition of raw materials and product risks.

The completion and stability of quality system and GMP compliance, and knowing the condition of raw materials and product risks.

Suppliers Evaluation

- General Evaluation based on Suppliers assessment mechanism

- Suppliers with scores lower than TTY requirement will be suspend from purchase contract and will be removed from supplier list.

Supplier Classification Management

- Classification according to supplier risk evaluation.

- Assist suppliers with improvement on the basis of grading results.

Suppliers Evaluation

TTY conducts daily and annual evaluations of raw material suppliers with transactions, and conducts evaluations in classifications of delivery time, quality, customer complaint, support and sustainability, as the basis for risk management.

TTY conducts daily and annual evaluations of raw material suppliers with transactions, and conducts evaluations in classifications of delivery time, quality, customer complaint, support and sustainability, as the basis for risk management.

| Annual Evaluation | General Evaluation |

|

Scores will be deducted for any abnormality on material delivered by suppliers and will be referred to for annual evaluation. |

Supplier Annual Monitoring

Through paper review or on-site audit to defined the classification according to supplier risk evaluation.

Other than routine quality surveys, the Taipei headquarters and purchase teams each perform a Sustainable Supplier Review as well as giving an assessment score. Each site then selects the suppliers it needs.

Through paper review or on-site audit to defined the classification according to supplier risk evaluation.

Other than routine quality surveys, the Taipei headquarters and purchase teams each perform a Sustainable Supplier Review as well as giving an assessment score. Each site then selects the suppliers it needs.

Questionnaire

Paper review is conducted through the document provided by suppliers and the “Sustainable Supplier Evaluation Questionnaire”, and on-site audit proceeded if necessary.

In year 2024, Chungli factory conducted 2 on-site inspections for 2 suppliers, and Lioudu factory 3 times.

Paper review is conducted through the document provided by suppliers and the “Sustainable Supplier Evaluation Questionnaire”, and on-site audit proceeded if necessary.

In year 2024, Chungli factory conducted 2 on-site inspections for 2 suppliers, and Lioudu factory 3 times.

On-site Audit

suppliers to provide following information as the reference standard:

suppliers to provide following information as the reference standard:

- Company Introduction, product supply, capacity, process description, facility and equipment introduction.

- Environment Safety, and Hygiene Management:

Information regarding environment overall safety, hygiene control and management, waste control, cross-contamination prevention.

- Certificates and Licenses:

Acquired government or global certified QC documents (PIC/S GMP or ISO 9001) and certification of environment management system (ISO 14001).

- Quality System Management:

Procedure document regarding the handling of CC (Customer Complaint), defects, abnormality management, change management, and corrective and preventive action.

- Raw Material Information:

SDS and COA, production procedure.

Supplier Classification Management

| Grade | Risk | Scores | Measures |

| A | Low | 90~100分 | 1.Suppliers to be considered when new items are required to be purchased. 2.Paper review based inspection. |

| B | Medium | 70~89分 | 1.Normal purchase contract. 2.Paper review based inspection. Suppliers should provide action plan according to the inspection results. When the improvement fails to meet TTY requirement, on-site audit will be conducted. |

| C | high | ≦69分 | 1.Cease the purchase of items from the suppliers. 2.Marked as disqualified suppliers and the contract is terminated. |